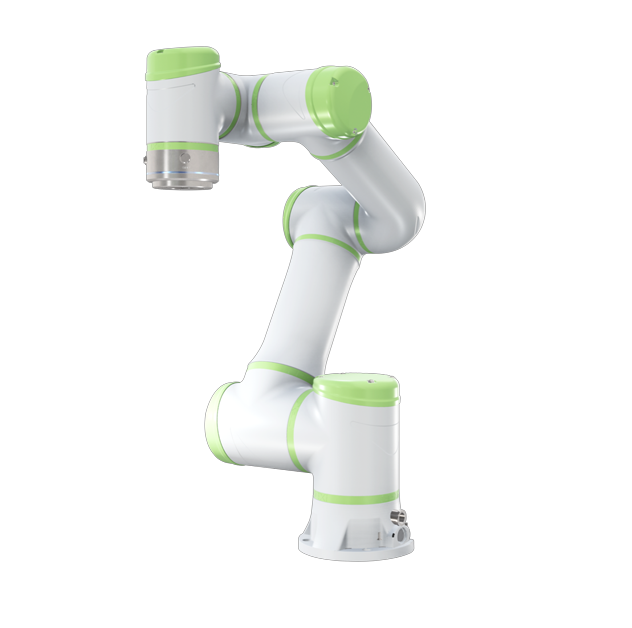

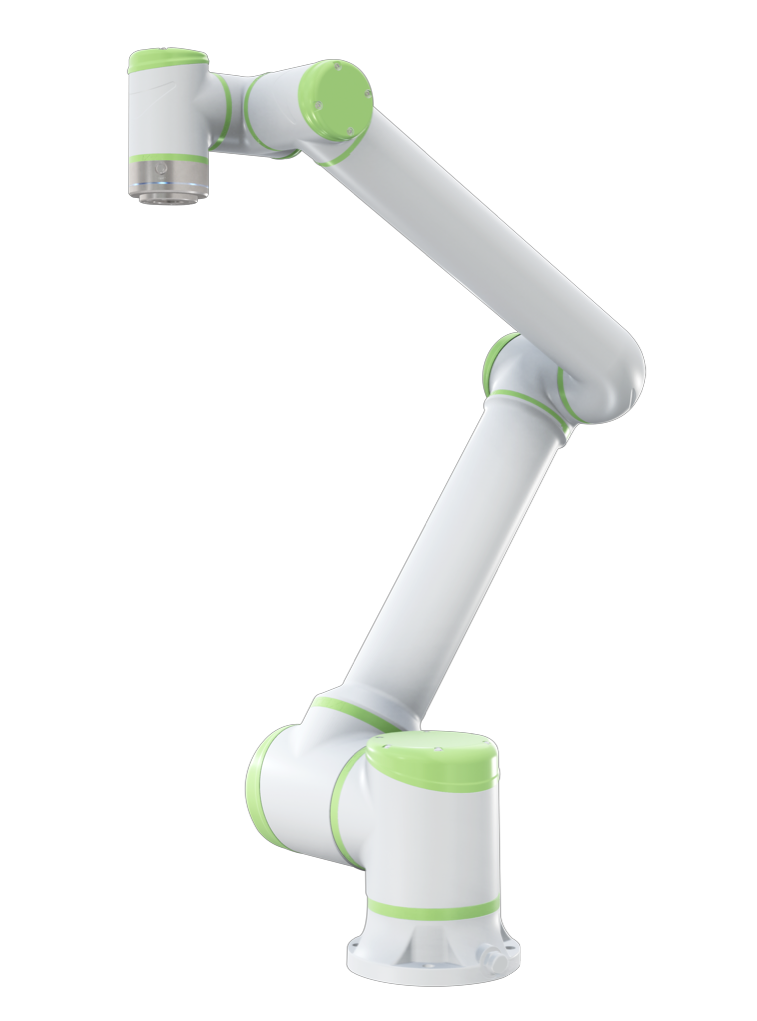

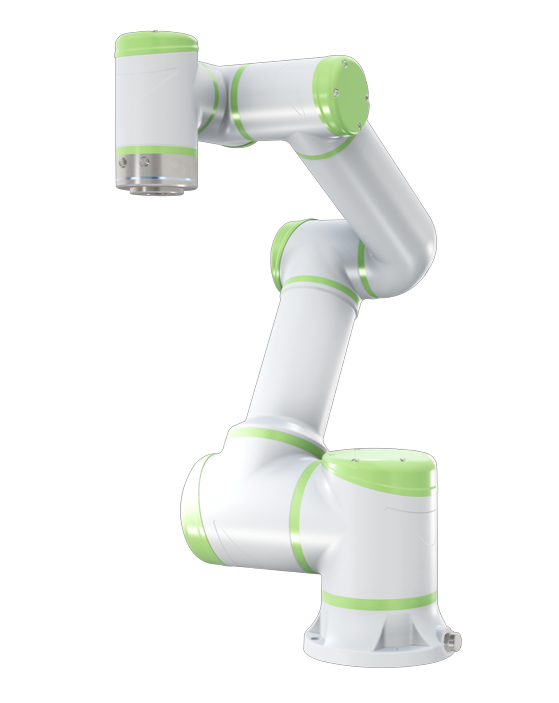

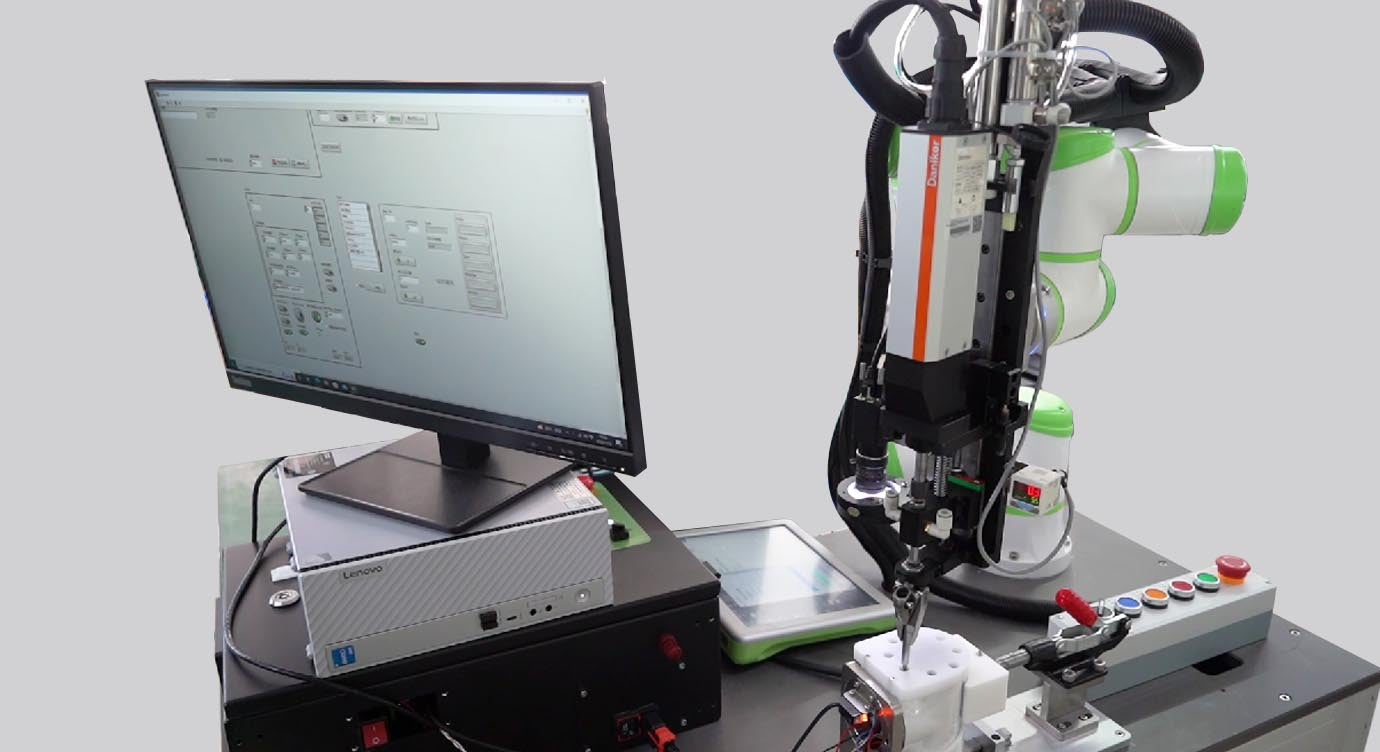

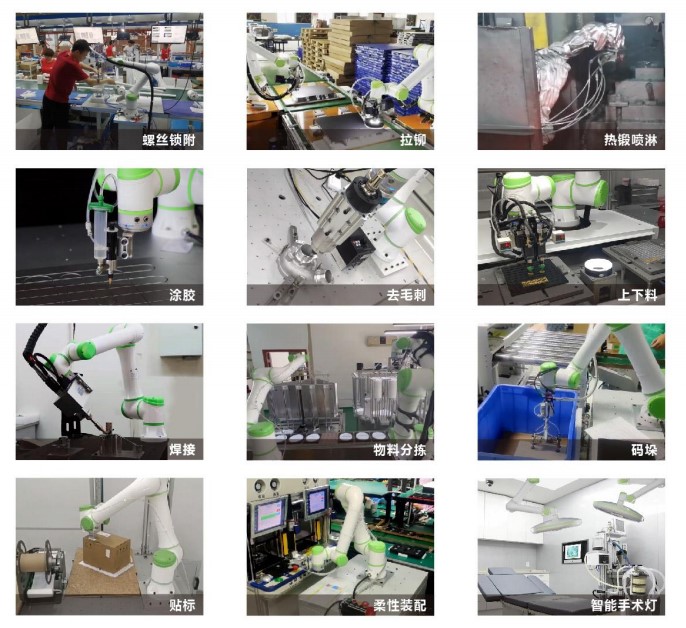

1. Human-robot collaboration requires no fence, takes up little space, and can be quickly deployed on site to complete welding operations.

2. It is simple to operate, can be taught by dragging, and is easy to program. It has high stability and consistency, making product quality easier to control.

3. It can reduce spatter and welding slag, make the weld seam beautiful, reduce the difficulty of welding and improve the quality of welding.

4. The program can be saved and reused, which saves manpower and material resources and greatly reduces the training cost of new employees.

5. It can quickly adapt to various flexible welding application tasks in small batches, laying the foundation for the realization of production line automation.

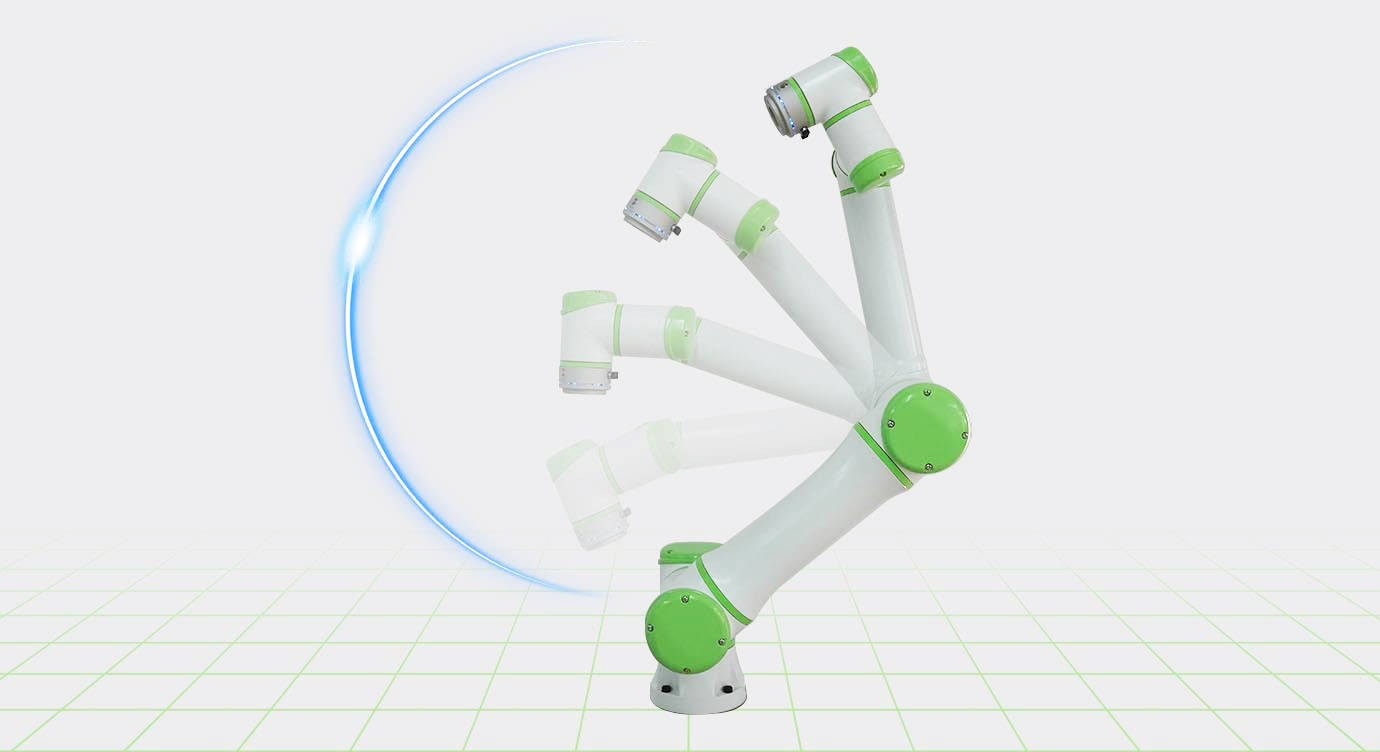

6. It does not require complex programming. Teaching 3 points can complete the 450° circular curve drawing action.