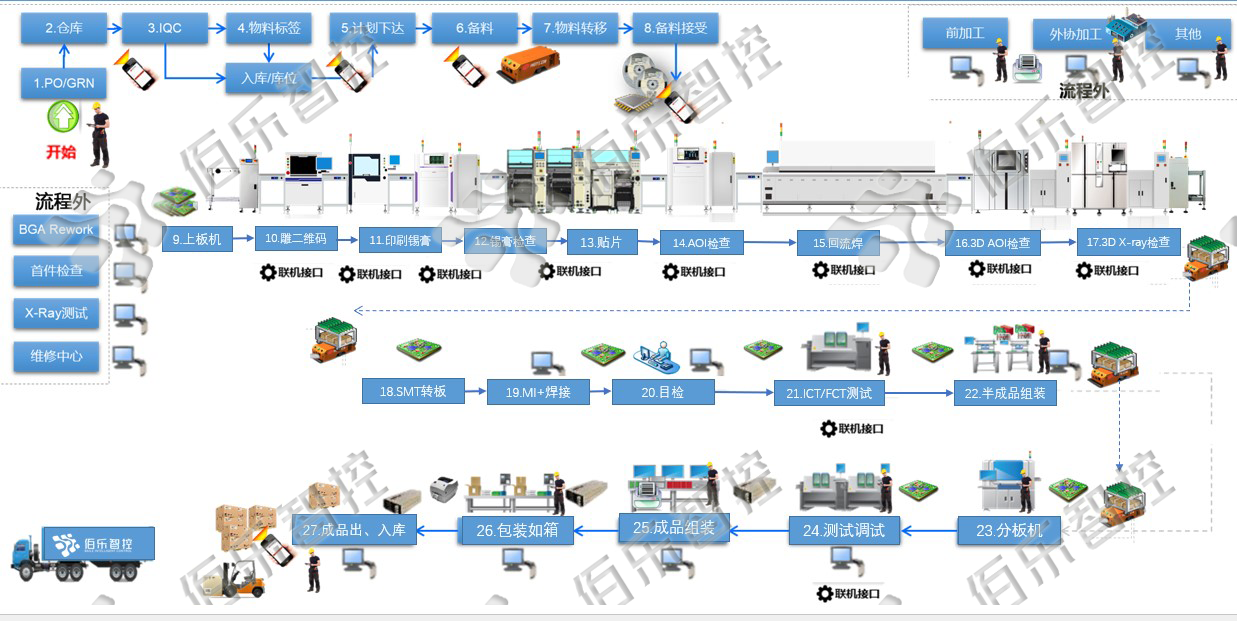

Achieve advantages such as error - proof material handling, rapid line change, offline material preparation, and online material continuation.;

Support the mixed production of multiple production lines and multiple work orders;

Realize the Just In Time (JIT) material shortage warning;

Uninterrupted line - stop material replacement and material continuation.